Cool Glass Fusing Techniques and Materials

Here are some of the materials used in glass fusing.

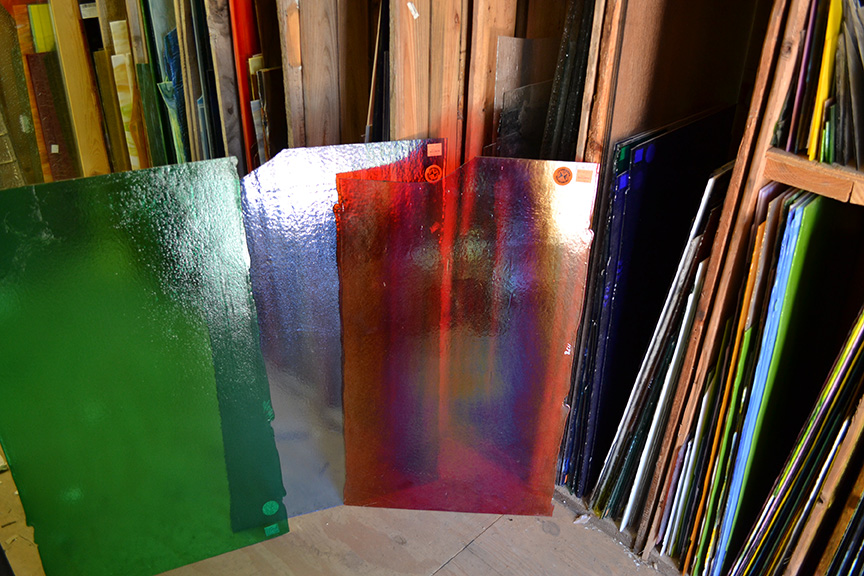

Sheet Glass is cut into shapes, layered then fused together.

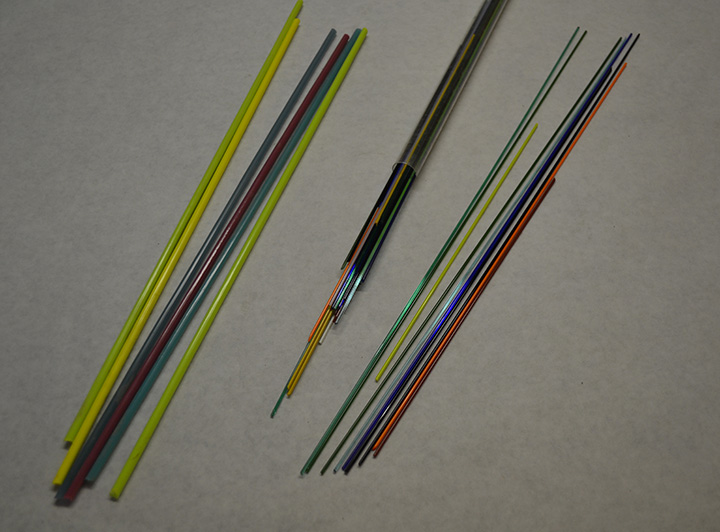

Rods and Stringers

Glass Confetti

Glass Frits and Powders

Cool Techniques

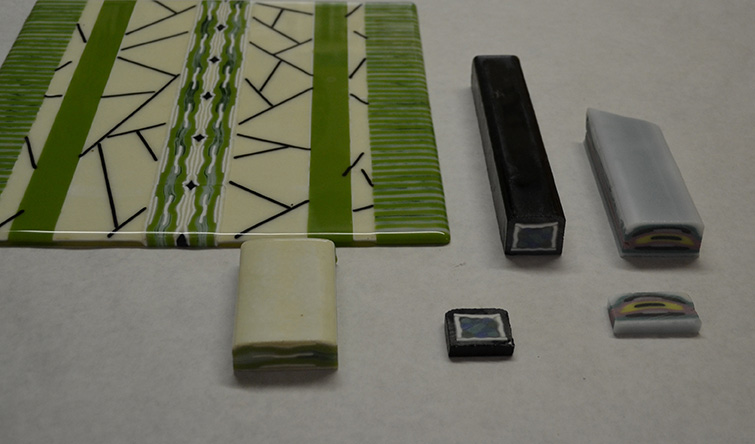

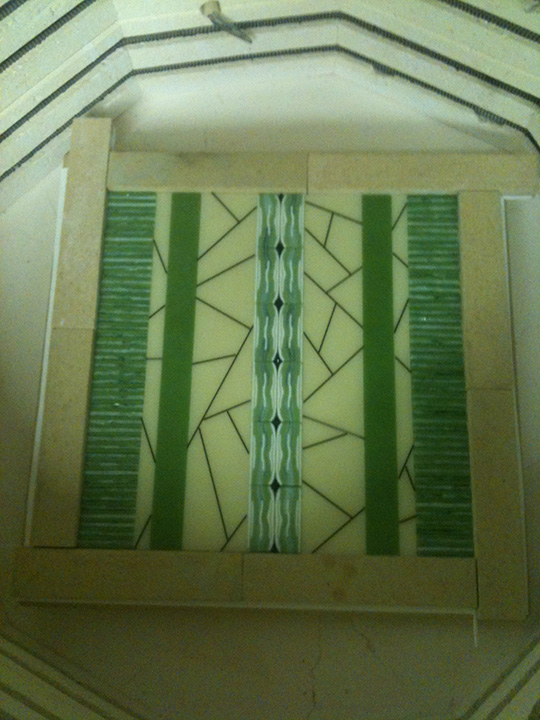

Pattern Bars

Bars made of glass pieces fused together that are then sliced on a wet saw and arranged to make designs.

On the right is the bar and on the left the slices of the bar laid out.

In the kiln ready to fire.

Fired to full fuse.

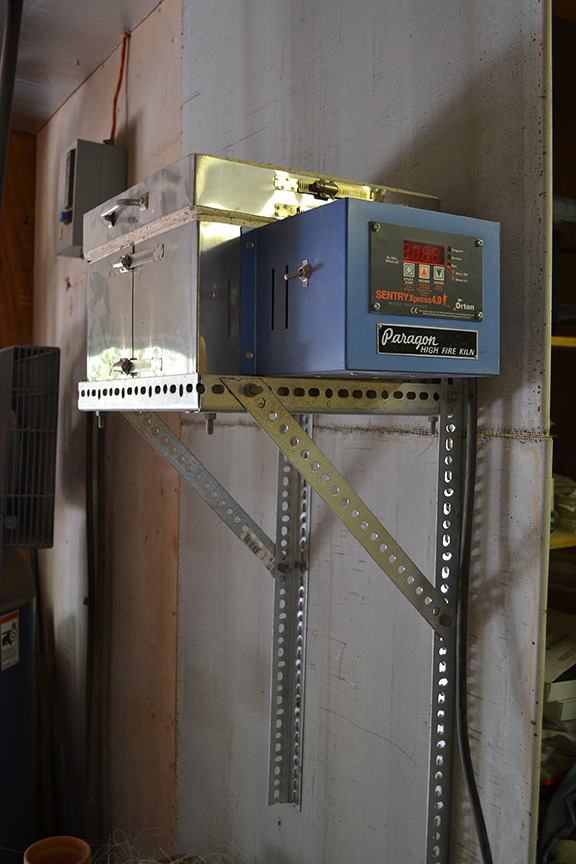

Vitrograph Kiln

A Vitrograph Kiln is a bottom draw glass furnace. In glass blowing you gather the glass from the top, in this case the glass flows out of the bottom of the furnace where it can be manipulated. Our Vitrograph is a small Paragon kiln with the bottom fire brick removed and replaced with a high temp board that has a hole cut in it. We have put cement board on the wall and used metal angle brackets to hang the kiln in the air for access to the bottom.

A pot of glass pieces is place inside the Vitrograph and fired to around 1700 degrees. This is done slowly so the glass melts evenly and flows out of the hole. The temperature can be adjusted up or down to make thicker (cooler temp) or thinner (hotter temp) stringer and hot parts.

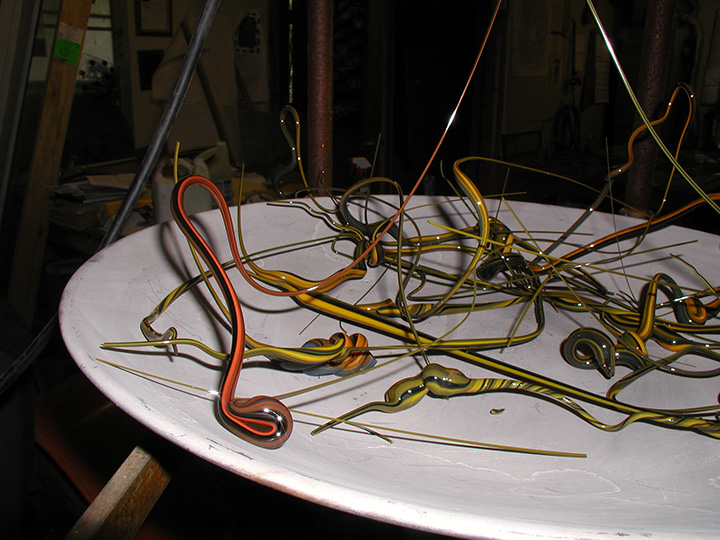

Hot parts from the Vitrograph that will be added as design elements to a fused glass project.

One of the pieces from this run. This was after it cooled down of course.

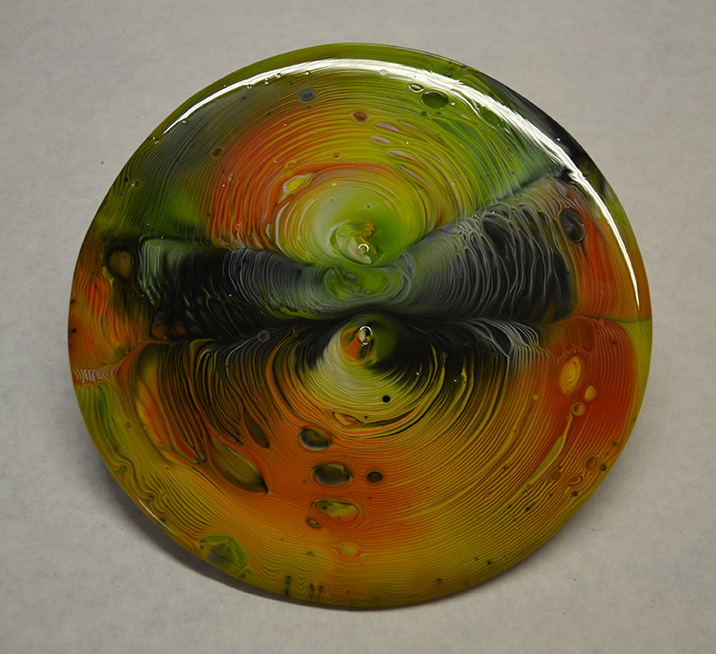

Pot Melts

Pot melts are done by placing glass in a container with one or more holes in the bottom of it. Ceramic flower pots work very well for this. The pot is suspended above the bottom of the kiln, when it is heated the glass flows out through the hole onto a kiln shelf below. It twists and turns together making very intricate patterns. Different numbers, sizes, and shapes of the holes will change the patterns in the final piece. For instance with round holes there tends to be a swirling pattern, and with rectangular holes or slots the pattern tends to look more folded. In the example below we used three round holes which gave us three distinct swirling patterns in the piece.

Set up and ready to fire.

After firing.

Look at the intricate detail in the sheet made by the pot melt.

Screen Melts

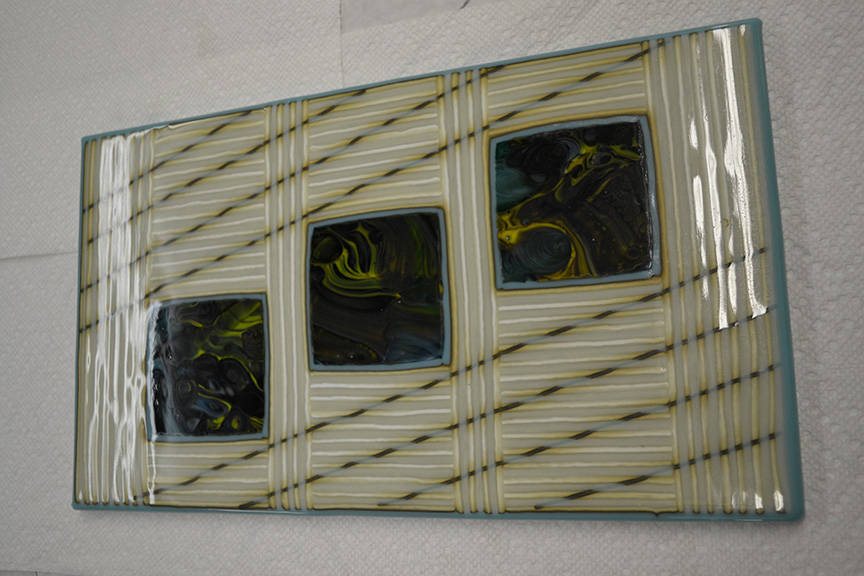

Screen melts are similar to pot melts except in place of the pot a metal screen is used to place the glass on and melt through. This creates hundreds of swirling pattern that merge with one another creating a very intricate pattern. Like the pattern bars and pot melts these pieces can then be cut and fused into a larger composition.

Screen melt after firing.

Screen melt sheet.

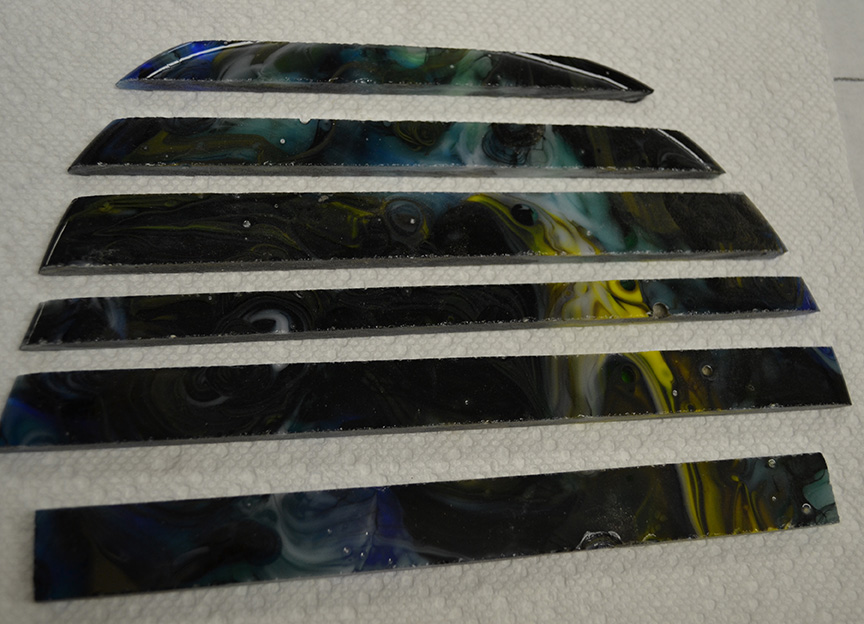

Screen melt sheet cut in strips.

Screen melt pieces used in a strip construction project.

Those are just a few of the really amazing techniques that are used in glass fusing, and people are coming up with new things every day. Glass is such a great medium, the possibilities are endless.

Click here for a Glossary of terms associated with glass fusing.

| Home | Stained Glass Windows | Beveled Windows | Etchings and Carvings |

| Fused and Bent Glass | Mosaics | Lamps | Ordering Custom Work |

| Religious Works | Restoration and Protective Glazing | Great Links | Resume |

| Special Events and Info | Like us on

|

Follow us on |

Connect with us on |